ICP sensors, or Injection Control Pressure sensors, are small but play important roles in ensuring the smooth operation and peak performance of your robust 7.3 Powerstroke. We often neglect this simple sensor, but the fact is that this tiny thing is very crucial to engine smoothness and performance. Ignoring the importance of ICP sensors can lead to severe consequences.

One of the most annoying problems you might experience is a difficult start, which frequently comes with various engine runability problems, such as unsettling stalling episodes, engine misfires, and the unsettling sensation of surging and bucking while driving.

In this article, we will cover all the 7.3 Powerstroke ICP sensor failure symptoms, how to diagnose, and the step-by-step replacement process of the ICP sensor. Whether you are an experienced mechanic or a vehicle owner interested in gaining insights into the inner workings of your dependable machine, this article will help you navigate the challenges associated with ICP sensors.

Understanding the 7.3 Powerstoke ICP Sensor

Let’s start by understanding the role of the ICP sensor. The Injector Control Pressure sensor, or ICP sensor, is a vital component responsible for monitoring and controlling the high-pressure oil system that drives the fuel injectors in your 7.3-liter Power Stroke engine. It plays a pivotal role in ensuring the engine runs smoothly and efficiently. A faulty ICP sensor can disrupt communication, show several engine performance issues, and trigger various DTC codes, such as:

- P1316 Code on 7.3 Powerstroke

- P1280 Code on 7.3 Powerstroke

- P121 Code on 7.3 Powerstroke, and so on.

7.3 Powerstroke ICP Sensor Failure Symptoms: 5 Common Problem To Address

Before we delve into the diagnostic process, it’s crucial to recognize the common symptoms that might indicate a malfunctioning ICP sensor. These symptoms include:

1. Cranking with No Start:

When you attempt to start your engine, you may notice that it cranks persistently but fails to start. This symptom is often a telltale sign of ICP sensor issues. The ICP sensor plays a pivotal role in regulating the high-pressure oil system required for the fuel injectors to function correctly. When the ICP sensor malfunctions, it can disrupt the precise fuel injection timing, leading to a no-start condition. Similarly, a failing HPOP can result in insufficient oil pressure in the high-pressure oil system. Without adequate pressure, the fuel injectors won’t receive the necessary high-pressure oil to perform optimally. This can result in poor fuel atomization, reduced power, and difficulty starting the engine. To resolve this case, you need to replace your 7.3 high-pressure oil pump.

2. Misfires:

A malfunctioning ICP sensor can result in engine misfires. Misfires occur when the timing of fuel injection becomes erratic or imprecise due to inaccurate pressure regulation by the ICP sensor. This can lead to a noticeable loss of power and engine performance. Misfires are not only a performance concern but can also contribute to increased exhaust emissions and reduced fuel efficiency.

3. Rough, Erratic Idling:

Your engine’s idle should be smooth and consistent. However, when the ICP sensor fails, the engine may exhibit a rough and erratic idle. You might feel vibrations, hear unusual noises, or sense irregular fluctuations in RPM (revolutions per minute) when the engine is idle. This rough idling can be bothersome and indicates an underlying issue that needs attention.

4. Stalling and Lack of Power:

Stalling refers to the abrupt shutdown of your engine while it’s running. A malfunctioning ICP sensor can cause your engine to stall unexpectedly, leaving you in an inconvenient or potentially hazardous situation. Additionally, you might experience a significant reduction in engine power during acceleration. This lack of power can make it challenging to merge onto highways or overtake slower vehicles, compromising both safety and convenience.

5. Surging or Bucking:

Surging and bucking are terms used to describe irregular and uneven engine performance, typically felt while driving. If your vehicle surges at idle or exhibits a bucking sensation while driving, it can be unsettling and unsafe. These symptoms often indicate that the ICP sensor is struggling to maintain consistent pressure in the high-pressure oil system, leading to fluctuations in fuel injection and engine performance.

Responding to a Faulty 7.3 Powerstroke ICP Sensor: Steps to Take

When you detect a bad 7.3 Powerstroke ICP sensor, the best course of action is to replace it promptly. There are no viable repair options, and running the engine without a functioning ICP sensor can lead to further complications. Ignoring the issue may result in poor engine performance, misfires, and even stalling. To prevent these problems and ensure your Powerstroke engine runs smoothly, change the faulty ICP sensor as soon as possible.

Diagnosing the 7.3 Powerstroke ICP Sensor

When faced with these symptoms, a systematic diagnostic approach is essential:

1. Check for Error Codes

Begin by retrieving error codes from your vehicle’s computer system. These codes can provide valuable insights into the nature of the problem and point you in the right direction for further diagnosis.

2. Inspect for Oil Leaks

Examine the ICP sensor for oil leaks. If you find oil inside the sensor, it’s a clear indicator that it needs replacement. Additionally, check the integrity of the O-ring situated between the sensor and the engine head. A damaged O-ring can lead to oil leakage and sensor malfunction.

3. Examine the ICP Passage

Ensure the ICP passage, where it connects to the engine head, isn’t blocked or obstructed. Any blockages in this passage can affect the sensor’s performance.

4. Inspect Wiring

Carefully examine the wiring connected to the ICP sensor for any visible damage, shorts, or open circuits. Verify that the sensor receives a stable 5-volt signal with the ignition on (but the engine is not running). Any deviations from this expected voltage could indicate wiring problems.

5. Valve Cover Check

Pay close attention to the wiring harness connections at the valve cover. These connectors have a propensity to rub against the valve cover, leading to shorts or electrical issues. To prevent this, consider using heavy-duty duct tape or a protective barrier between the valve cover and the wiring harness.

Testing the 7.3 Powerstroke ICP Sensor

When testing the 7.3 powerstroke ICP sensor, follow these steps:

Unplug the sensor

In the case of a no-start situation or if your vehicle stalls, try unplugging the ICP sensor. This action prompts the vehicle’s computer to use a default pressure of approximately 700 PSI. While this won’t provide optimal performance, it can allow you to limp off the road or reach a safe location.

Check the Plug:

Ensure that the ICP sensor plug receives a stable 5-volt reference signal and doesn’t read excessively high or low values. Anomalous readings could indicate wiring problems or, in rare cases, issues with the Powertrain Control Module (PCM).

Revive Your 7.3 Powerstroke: How Much Does a New ICP Sensor Cost?

Replacing a bad 7.3 Powerstroke ICP (Injector Control Pressure) sensor is not typically expensive in terms of the cost of the sensor itself. On average, a high-quality ICP sensor for a 7.3 Powerstroke engine can range from $50 to $80, depending on the brand and where you purchase it. However, if you choose to have a mechanic do it, the cost of labor for installation can add to the overall expense.

The good news is that replacing the ICP sensor is a relatively straightforward process that doesn’t require extensive labor. If you have basic mechanical skills and the necessary tools, you can often replace it yourself, saving on labor costs. This can make the overall expense quite reasonable. Below, we’ll outline the basic steps to replace the ICP sensor:

Additionally, considering the critical role the ICP sensor plays in the proper functioning of your engine, investing in a high-quality replacement is advisable. Cheaper sensors may be less expensive upfront but can lead to further issues and potentially more significant repair costs down the line.

Replacing the ICP Sensor of The 7.3 Powerstroke Engine

If you’ve determined that the ICP sensor needs replacement, here are the steps to follow:

Gather Tools:

- You’ll need basic hand tools such as wrenches.

- sockets, and

- the new ICP sensor.

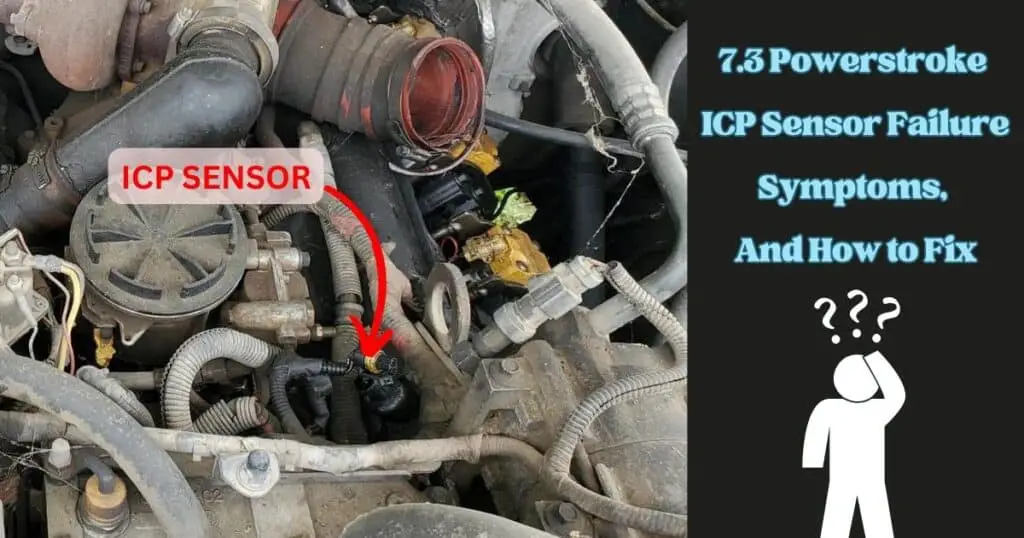

Locate the 7.3 Powerstroke ICP Sensor:

The 7.3 Powerstroke ICP Sensor is typically located on the driver’s side of the engine, towards the front, on the cylinder head around the high pressure oil pump (HPOP).

Disconnect Wiring:

Carefully unplug the wiring harness connected to the old sensor.

Remove the Old Sensor:

Using an appropriate wrench or socket, carefully unscrew and remove the old ICP sensor from the cylinder head. Be cautious not to damage the threads or the surrounding area.

Install the New Sensor:

Screw in the new ICP sensor by hand to avoid cross-threading. Then, use your wrench or socket to secure it snugly. Remember not to overtighten.

Reconnect Wiring:

Attach the wiring harness to the new sensor.

Why Quality Matters While Choosing The 7.3 Powerstroke ICP Sensor

When it comes to purchasing a replacement ICP sensor, quality is paramount. It’s worth noting that the quality of the ICP sensor matters significantly. Cheaper, lower-quality sensors may not function correctly and can lead to further issues down the road. Investing in a reliable, high-quality sensor is a wise choice to ensure the long-term health of your Powerstroke engine.

Maintenance and Preparedness

Keep spare parts:

To avoid getting stranded on the side of the road due to ICP sensor issues, consider keeping spare ICP and Injection Pressure Regulator (IPR) sensors, as well as a cam sensor, in your vehicle. These simple precautions can save you from significant inconvenience, costly towing expenses, and downtime.

Regular maintenance:

Stay on top of regular maintenance tasks to prevent issues before they occur. This includes oil changes, fuel filter replacements, and checking for oil leaks.

When Should You Check Your 7.3 Powerstroke ICP Sensor

Inspecting the ICP (Injector Control Pressure) sensor on a 7.3 Powerstroke engine is an essential part of routine maintenance to ensure the engine’s optimal performance. While there isn’t a specific mileage interval for inspecting the ICP sensor, it’s recommended to incorporate it into your regular maintenance schedule. Here are some guidelines to follow:

- During Routine Maintenance: When performing routine maintenance tasks such as oil changes, fuel filter replacements, and overall engine checks, it’s a good practice to inspect the ICP sensor. This can be done every 15,000 to 20,000 miles or as recommended in your vehicle’s service manual.

- When Symptoms Arise: If you notice any of the common symptoms associated with ICP sensor issues, such as hard starting, misfires, rough idling, stalling, or loss of power, it’s advisable to inspect the sensor promptly. These symptoms may indicate a problem with the ICP sensor or related components.

- After Repairs or Modifications: If you’ve recently performed any repairs or modifications to your 7.3 Powerstroke engine, especially those involving the high-pressure oil system, it’s a good idea to inspect the ICP sensor to ensure it wasn’t inadvertently damaged during the work.

- As Part of a Diagnostic Process: When troubleshooting engine issues or running diagnostic tests using a scan tool, checking the ICP sensor’s data can help identify problems. If abnormal readings are detected, it may warrant a closer inspection of the sensor.

Conclusion

At this point we believe, you already learned that the ICP sensor is a critical component of your 7.3-liter Power Stroke engine. Understanding its function, recognizing common symptoms, and following a systematic diagnostic process is essential for maintaining a trouble-free driving experience. By staying proactive, investing in quality sensors, and keeping spare parts on hand, you can ensure that your truck runs smoothly and reliably for years to come.

Last Updated on February 18, 2025 by Rifen